2009

YEAR

PROJECT INFO

RISD + MIT Sloan

PROJECT TYPE

Industrial Design

SPECIFICATIONS

SolidWorks

3D Studio Max (Vray)

3D Printing

Alpha Prototyping

OVERVIEW

A collaborative semester course with the MIT Sloan School of Management. Our project group consisted of MIT Engineers, MBA, LFM, and myself as the Industrial Designer. Our supervisors were professor Steven D. Eppinger; author of “Product Design and Development” with Karl T. Ulrich, and Matt Kressy, founder of DesignTurn.

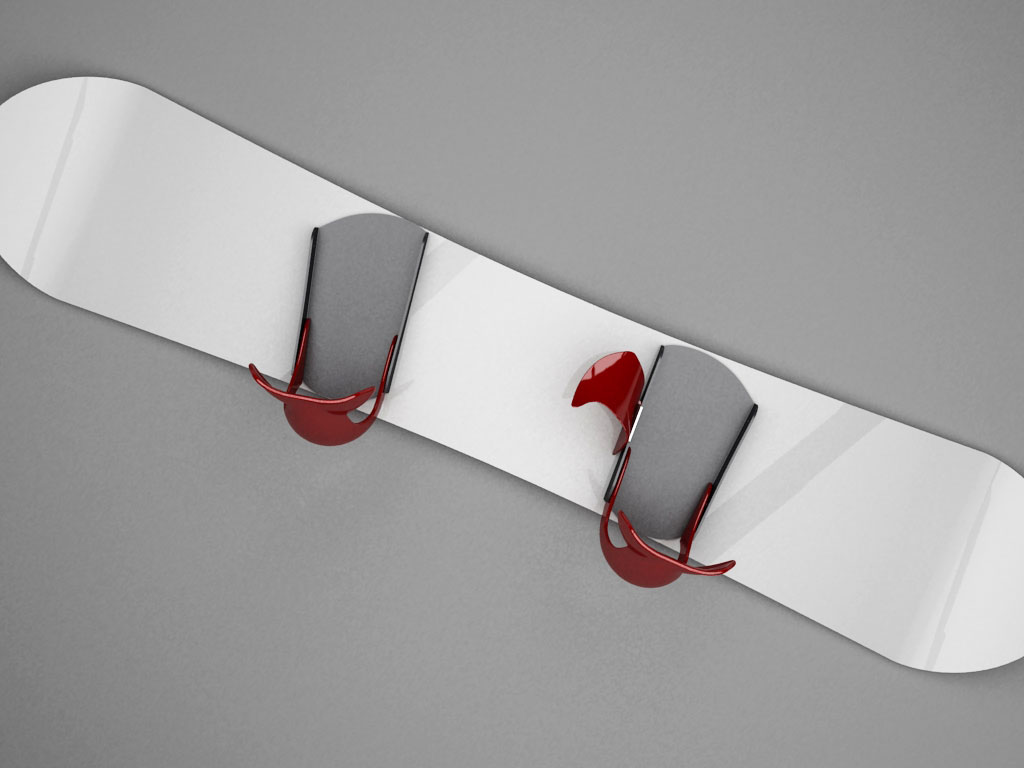

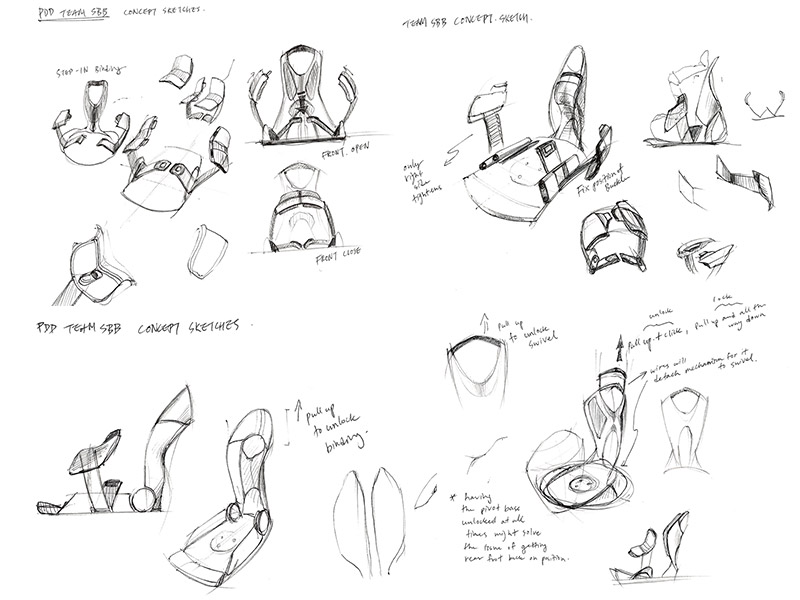

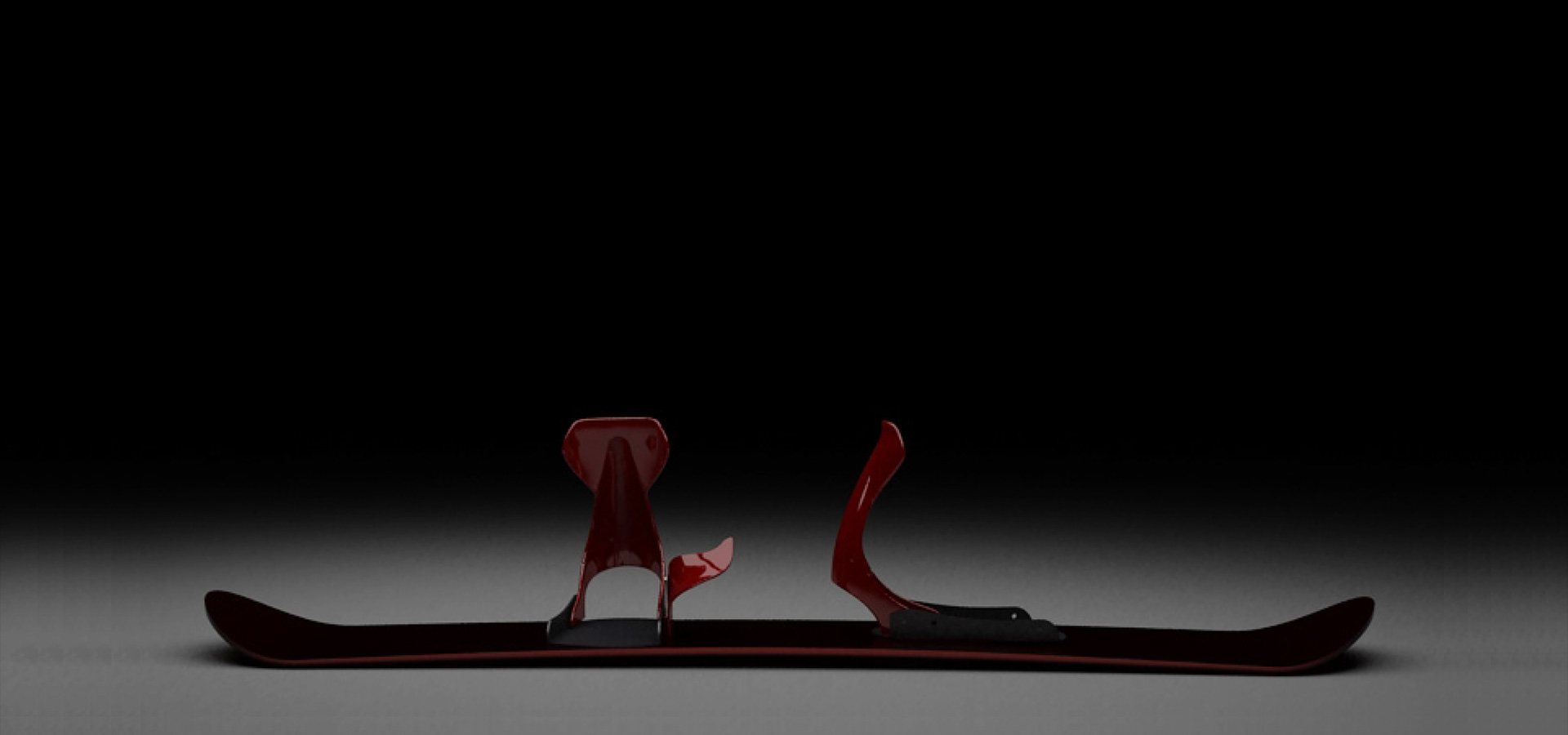

Our group identified an incredible opportunity to upgrade the current outdated snowboard with an innovative solution. The problem and issue are with the bindings. The “forward” foot is always intact with the board and is unable to pivot in a comfortable and natural position. This does not allow the user to be in a free “skating” position, when they are either going on/off lifts or maneuvering on flat catwalks. It also causes pain and injuries to your ankle, and accidents are easier to happen because of lack of control.

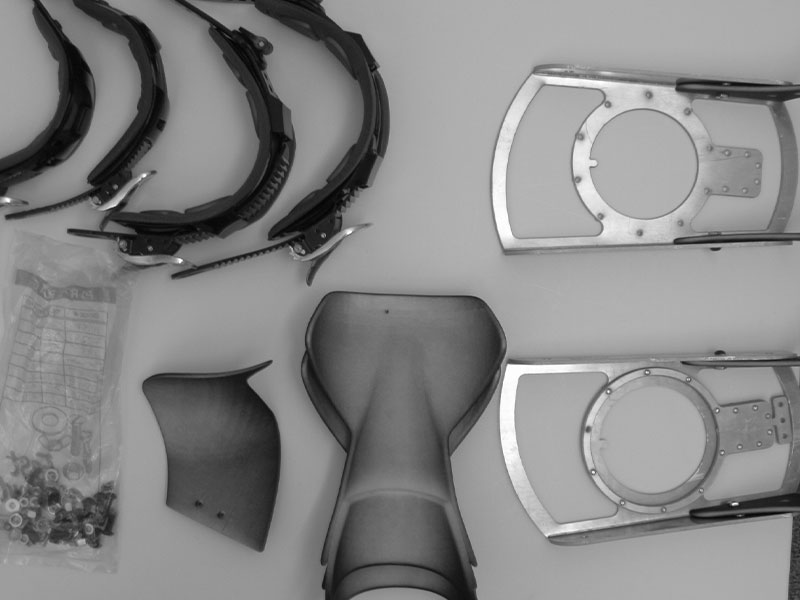

The MIT students were responsible for engineering, marketing, patents, and financial calculations for actual manufacturing. I was responsible for design as well as modeling an alpha-prototype. Our result was a combination of trend changing design and innovative engineering solutions.

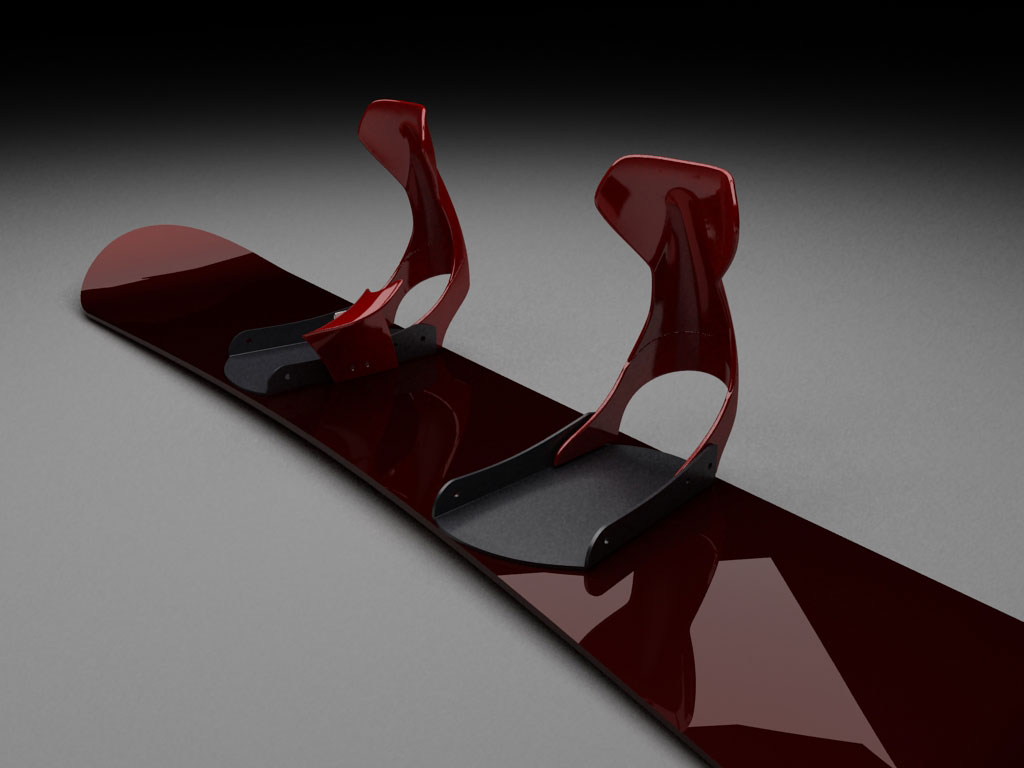

The fundamental function and design of snowboard bindings haven’t changed for more than 20 years, until now.

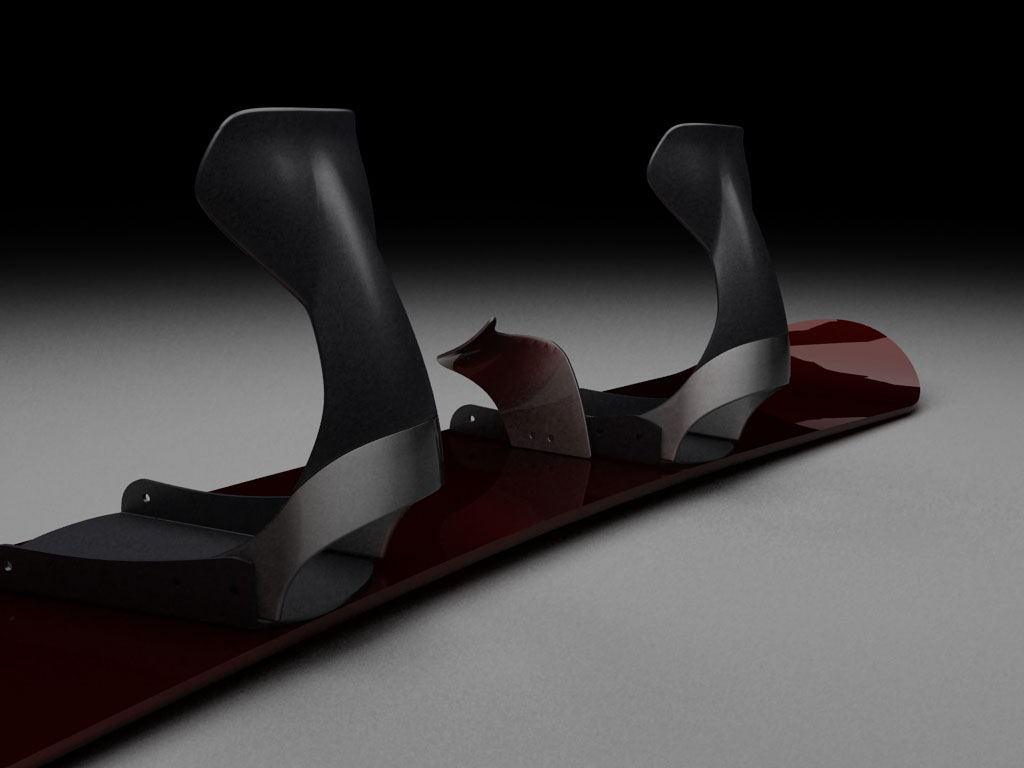

The main issue is with how the snowboard bindings are attached to the board. Your “forward” foot is usually attached when maneuvering before or after you finish a ride. After hours of researching, testing, and model making, we came up with a proprietary mechanism that allowed the rider to rotate the front binding to a “skating” position. Pulling a lever behind the binding will unlock the mechanism and allow the binding to rotate on the center mount. Once you are done skating, just rotate the front binding to riding position and the bindings will snap back to your secured position.

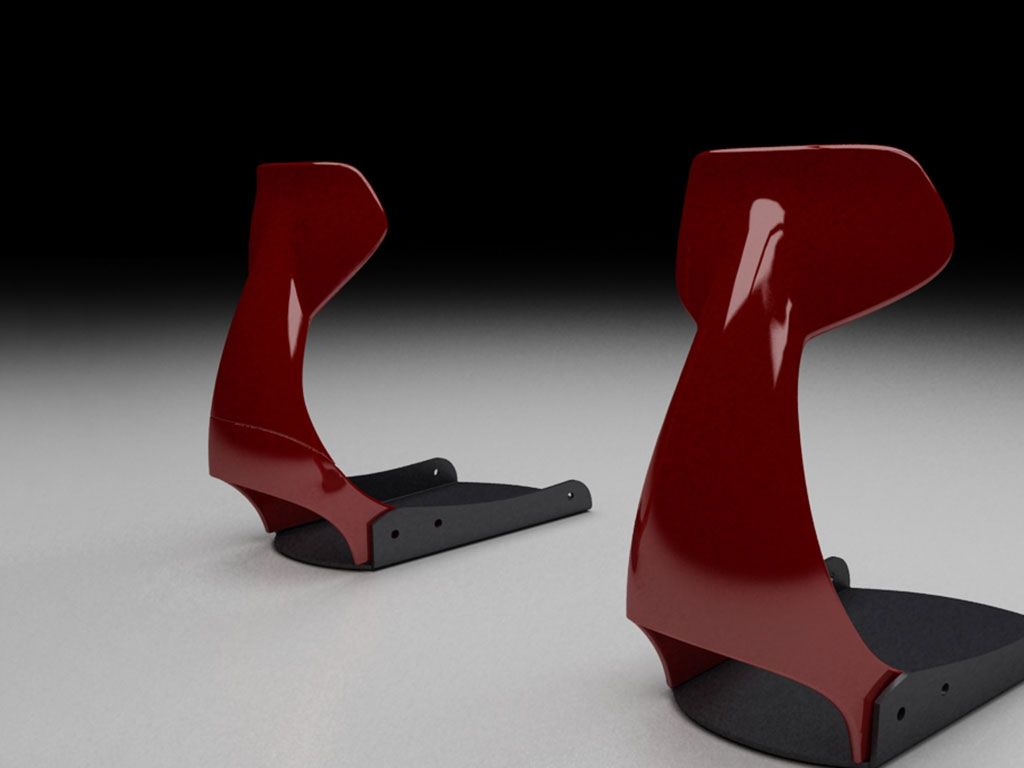

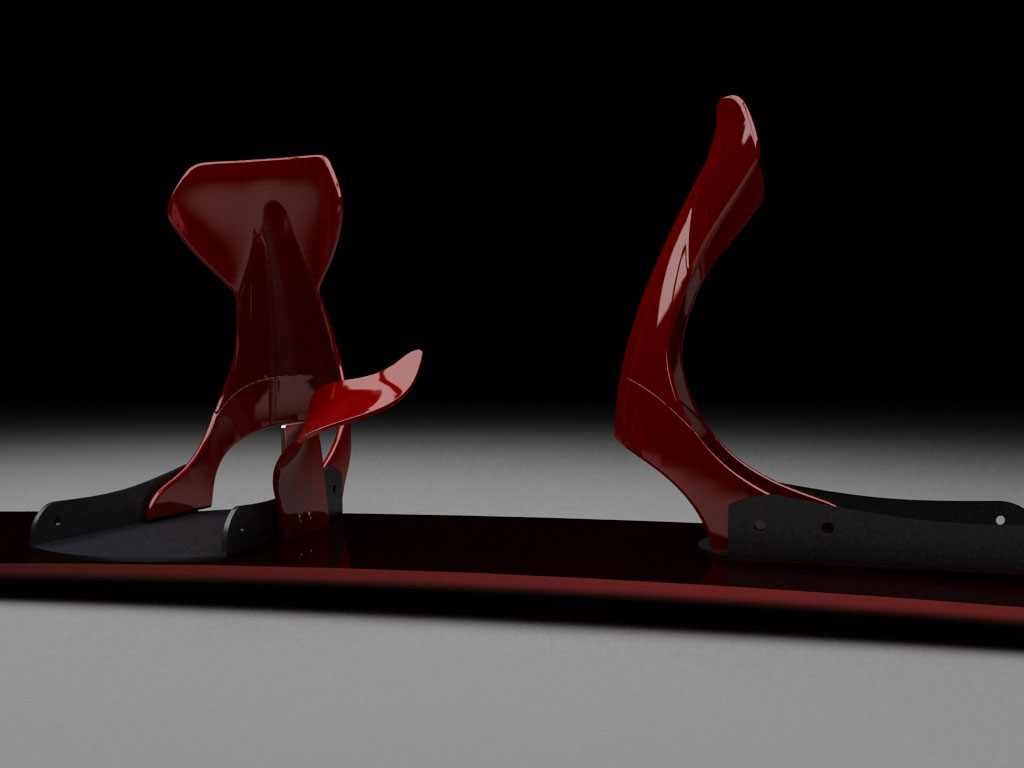

My design concept was inspired by Formula 1, especially with the Ferrari and red colors. Formula 1 cars are the world’s fastest and ultimate performance machines. Our concept was now the ultimate performance bindings.

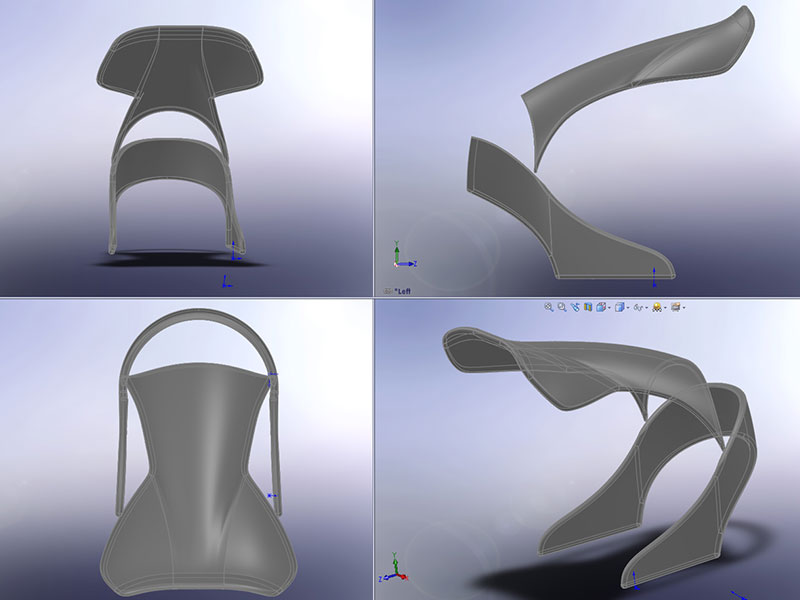

The wide top area wraps around the boots giving the best control and support. The clean surface with bold curves give an aerodynamic form. I believe my philosophy of creating something unusual and exciting that also captures the functionality is an aesthetic part of the form.

Because of the radical design in shape, we had to get our body pieces 3D printed. Our budget only allowed us to make one of each piece so having

an accurate rendering helped us reduce error and be able to deliver on time. We used waterjet to cut sheet aluminum and fabricated the base of the binding. Rapid prototyping to alpha stage was a requirement.